Major Industries That Rely on Epoxy Injection Molding

Major Industries That Rely on Epoxy Injection Molding

Blog Article

Exploring the Advantages of Epoxy Injection Molding for Effective Manufacturing Procedures

When you consider production procedures, epoxy injection molding sticks out for its performance and performance. This strategy combines the strength of epoxy materials with specific production capacities, allowing you to produce intricate layouts while decreasing waste. The fast curing times and high dimensional precision mean quicker production and lower prices. How does this translate into real-world applications and advantages for numerous markets? Allow's check out even more.

Summary of Epoxy Shot Molding

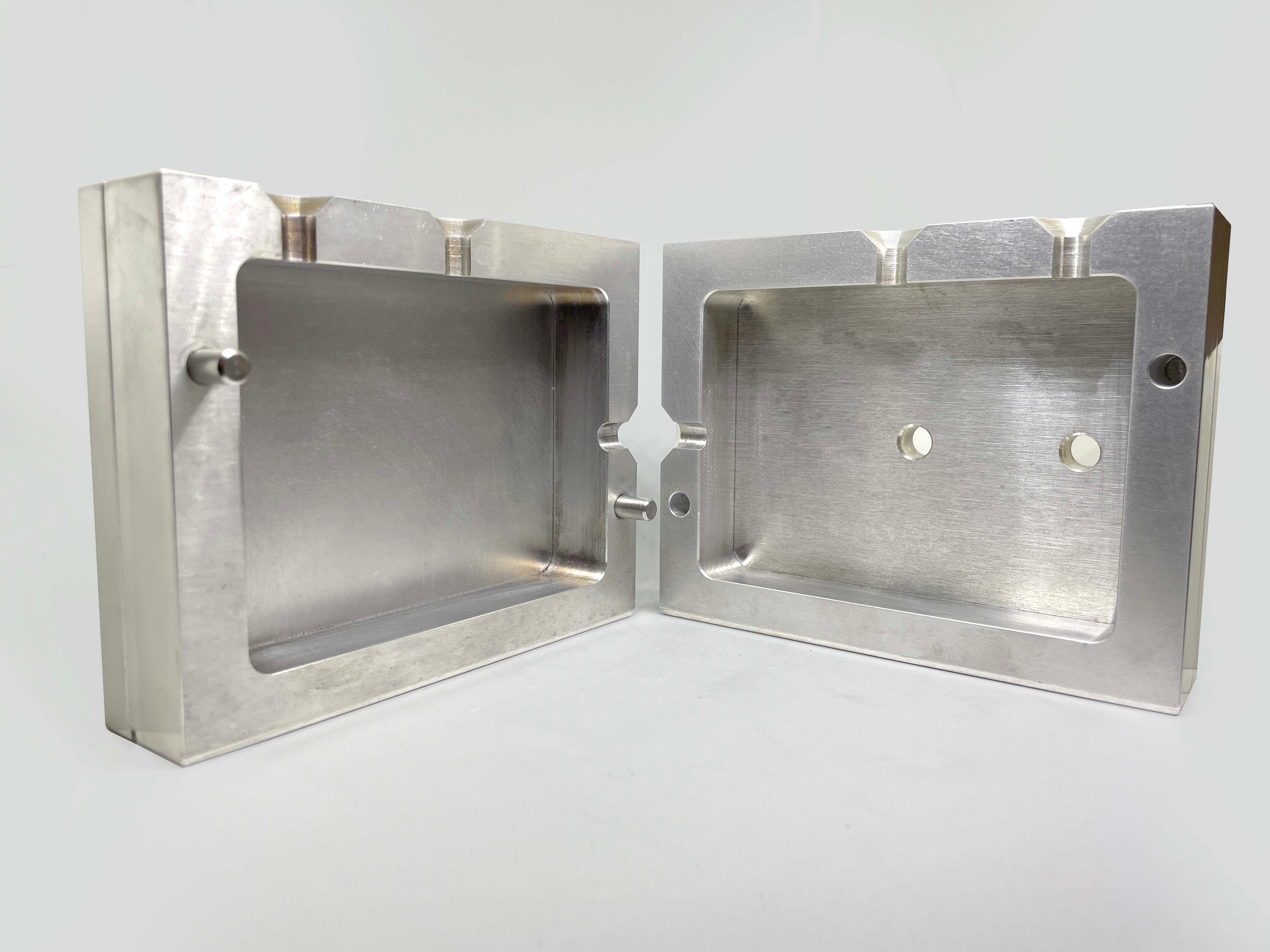

Epoxy shot molding is an extremely effective manufacturing process that combines the strength of epoxy resins with the precision of shot molding. You'll discover that this strategy enables the production of elaborate designs and intricate shapes, making it suitable for different applications. By injecting warmed epoxy into a mold and mildew, you accomplish quickly healing times and exceptional dimensional accuracy.This technique not just minimizes waste but also boosts manufacturing rate, providing you the ability to fulfill tight target dates. You can expect constant top quality across sets, as each molded component preserves uniform buildings. In addition, the flexibility of epoxy materials indicates you can customize the product residential properties to fit particular needs, such as thermal resistance or chemical stability. Overall, epoxy injection molding streamlines your manufacturing procedure while providing high-quality parts that can endure requiring atmospheres.

Advantages of Resilience and Toughness

Epoxy shot formed parts stand out in various applications when it comes to durability and stamina. You'll appreciate how these parts can endure harsh conditions, making them optimal for industries like automotive and aerospace. Their phenomenal mechanical buildings mean they resist wear and tear better than many choices, guaranteeing a longer lifespan for your products.In addition, epoxy's resistance to chemicals, dampness, and temperature level variations guarantees that your components remain trustworthy also in difficult settings. This resilience translates into lower maintenance costs and decreased downtime, permitting your manufacturing procedures to run smoothly.You'll likewise discover that epoxy injection formed parts keep their architectural honesty under stress, which is vital for safety-critical applications. By going with epoxy, you're purchasing robust options that can take care of the needs of your jobs, inevitably bring about raised customer contentment and count on your brand name.

Accuracy and Accuracy in Production

When you pick epoxy shot molding, you're buying boosted dimensional resistance and constant reproducibility - epoxy injection molding. This procedure assures that each component meets precise requirements, minimizing variants. You'll appreciate the dependability that originates from understanding your products will keep high requirements whenever

Improved Dimensional Resistance

Regular Reproducibility Specifications

Uniformity in reproducibility standards is essential for preserving accuracy and accuracy in production. When you make use of epoxy shot molding, you guarantee that each part you produce fulfills specific requirements each time (epoxy injection molding). This technique lowers variants, which means you will not lose time or resources on rework. You can trust that your mold and mildews will consistently produce components that fit perfectly within your assembly processes. In addition, with accurate control over the injection specifications, you accomplish harmony across batches, enhancing the overall top quality of your items. By sticking to regular criteria, you not just improve your manufacturing effectiveness however likewise raise client fulfillment, understanding they'll obtain high-grade and reliable items every single time. Welcoming these criteria can significantly boost your operational success

Reduction of Material Waste

When you pick epoxy injection molding, you're purchasing specific product use that minimizes waste. This approach lessens scrap generation, guaranteeing that all product counts. And also, it enables for effective recyclable inputs, making your manufacturing procedure a lot more sustainable.

Precise Product Usage

By making use of epoxy injection molding, you greatly lower product waste, which not only conserves expenses yet likewise profits the atmosphere. This procedure enables you to make use of exactly the correct amount of material required for each component, reducing unwanted. With accurate control over the shot process, you'll discover check here that the epoxy loads the mold flawlessly, guaranteeing that every decline counts. This accuracy results in less mistakes and reworks, improving total production effectiveness. Plus, by tailoring the material use to your specific requirements, you can maximize your supply chain and decrease stock prices. Ultimately, concentrating on exact product use helps you produce top quality products while advertising lasting techniques that add to a greener world.

Decreased Scrap Generation

Among the key benefits of epoxy injection molding is its ability to minimize scrap generation, significantly minimizing product waste in the production process. By specifically controlling the shot of resin, you ensure that every drop counts, resulting in much less excess material. Unlike typical techniques, where waste can stack up swiftly, epoxy shot molding concentrates on efficient material use, permitting you to produce premium components with very little leftovers. This not just web reduces your expenses however additionally simplifies waste management, making it less complicated to keep a cleaner work space. As you embrace this strategy, you'll locate that lowering scrap generation adds to a more sustainable manufacturing environment, enhancing your overall functional performance. Welcoming this innovation indicates you're taking a substantial action toward smarter manufacturing practices.

Reliable Recyclable Inputs

As you discover epoxy shot molding, you'll discover its capacity for utilizing reliable recyclable inputs, which greatly reduces product waste. This process enables you to incorporate recycled products, making certain that you're not just cutting prices however also adding to sustainability. By picking epoxy formulas that include recycled content, you can maintain product integrity while minimizing ecological effect. On top of that, the capacity to reuse scrap generated throughout production suggests you can redirect these products back right into the process, additional lowering waste. This strategy not only maximizes your production performance however also lines up with modern sustainability objectives. You'll find that spending in recyclable inputs enhances your functional performance, making your manufacturing processes much more green and cost-effective.

Adaptability in Style and Modification

You could think of standard molding procedures as rigid, epoxy shot molding supplies remarkable flexibility in style and modification. With this approach, you can create elaborate forms and intricate geometries that meet particular demands. You're not restricted to common styles; instead, you can tailor each product to fit your one-of-a-kind needs.This adaptability permits the combination of numerous attributes, such as undercuts and slim wall surfaces, which may be challenging to achieve with other methods. You can also easily customize styles for various applications without considerable retooling, making it less complex to adjust to changing market demands.Moreover, epoxy materials been available in an array of shades and coatings, providing you the imaginative liberty to boost visual appeals while making sure performance. By leveraging this flexibility, you can produce top quality components that stand apart in competitive markets, ultimately leading to greater customer complete satisfaction.

Cost-Effectiveness and Efficiency

When you consider the costs connected with production, epoxy shot molding attracts attention for its cost-effectiveness and performance. This method lowers product waste, permitting you to make the most of every buck invested in basic materials. You'll locate that the fast cycle times connected with epoxy shot molding cause faster manufacturing prices, enabling you to fulfill tight target dates without compromising quality.Additionally, the longevity of epoxy products indicates fewer problems and much less requirement for repair work or substitutes, additionally driving down prices. With lower maintenance requirements for mold and mildews and equipment, your total operational costs decrease, enabling a more structured manufacturing process.Investing in epoxy injection molding can bring about considerable lasting cost savings, making it a clever option for businesses intending to optimize their manufacturing procedures. You'll not only enhance your lower line however additionally improve your competitive edge out there.

Applications Across Various Industries

Epoxy injection molding discovers applications in a large range of sectors, showcasing its flexibility and performance. In the auto sector, you'll see it made use of for producing resilient elements like control panels and body components that stand up to severe conditions. In the electronic devices market, it's optimal for producing elaborate housings and circuit card that need high accuracy and reliability.If you're in the aerospace field, epoxy injection molding assists you make solid and lightweight elements, improving fuel efficiency. The medical market benefits, too, with custom-made molds for devices that demand high standards of health and safety.In construction, you'll find epoxy molding utilized for fittings and components, giving both Visit Website sturdiness and aesthetic charm. With its ability to adapt to numerous needs, epoxy shot molding confirms very useful throughout these diverse industries, making your production procedures smoother and extra efficient.

Regularly Asked Inquiries

Exactly How Does Epoxy Injection Molding Contrast to Standard Molding Techniques?

Epoxy injection molding supplies better accuracy and sturdiness contrasted to conventional approaches. You'll observe quicker production times and reduced material waste, making it an extra effective choice for your production requirements and enhancing total product quality.

What Kinds Of Epoxy Resins Are Typically Made Use Of in Injection Molding?

You'll commonly find numerous types of epoxy materials used in shot molding, including standard epoxy, fast-curing epoxy, and adaptable epoxy. Each type uses distinct residential or commercial properties, satisfying particular applications and efficiency requirements in different sectors.

Are There Any Type Of Limitations to Epoxy Injection Molding?

Yes, there are restrictions to epoxy injection molding. You may run into issues like longer healing times, higher prices compared to various other materials, and possible brittleness in certain applications, which can affect your manufacturing performance and product longevity.

Exactly How Do Healing Times Affect Production Speed?

What Precaution Are Required Throughout the Shot Molding Refine?

Throughout the shot molding process, you need to wear protective equipment, warranty correct air flow, maintain tools regularly, and comply with security procedures. These procedures aid stop accidents, injuries, and ensure a risk-free functioning setting for everyone included. Epoxy injection molding is an extremely reliable production procedure that combines the strength of epoxy materials with the accuracy of shot molding. One of the crucial advantages of epoxy injection molding is its ability to reduce scrap generation, considerably minimizing product waste in the manufacturing procedure. You may think of traditional molding procedures as inflexible, epoxy shot molding uses impressive adaptability in layout and modification. You'll locate that the fast cycle times linked with epoxy shot molding lead to faster production rates, enabling you to meet limited target dates without giving up quality.Additionally, the resilience of epoxy materials means fewer issues and much less need for substitutes or repair services, even more driving down prices. You'll frequently locate numerous kinds of epoxy resins used in shot molding, consisting of common epoxy, fast-curing epoxy, and versatile epoxy.

Report this page